Axus Technology

The order consists of multiple system configurations and applications, highlighting Capstone’s flexibility and Aksas’ single-wafer SiC processing expertise.

Axus Technology Sees SiC Order Momentum for Capstone CMP Platform

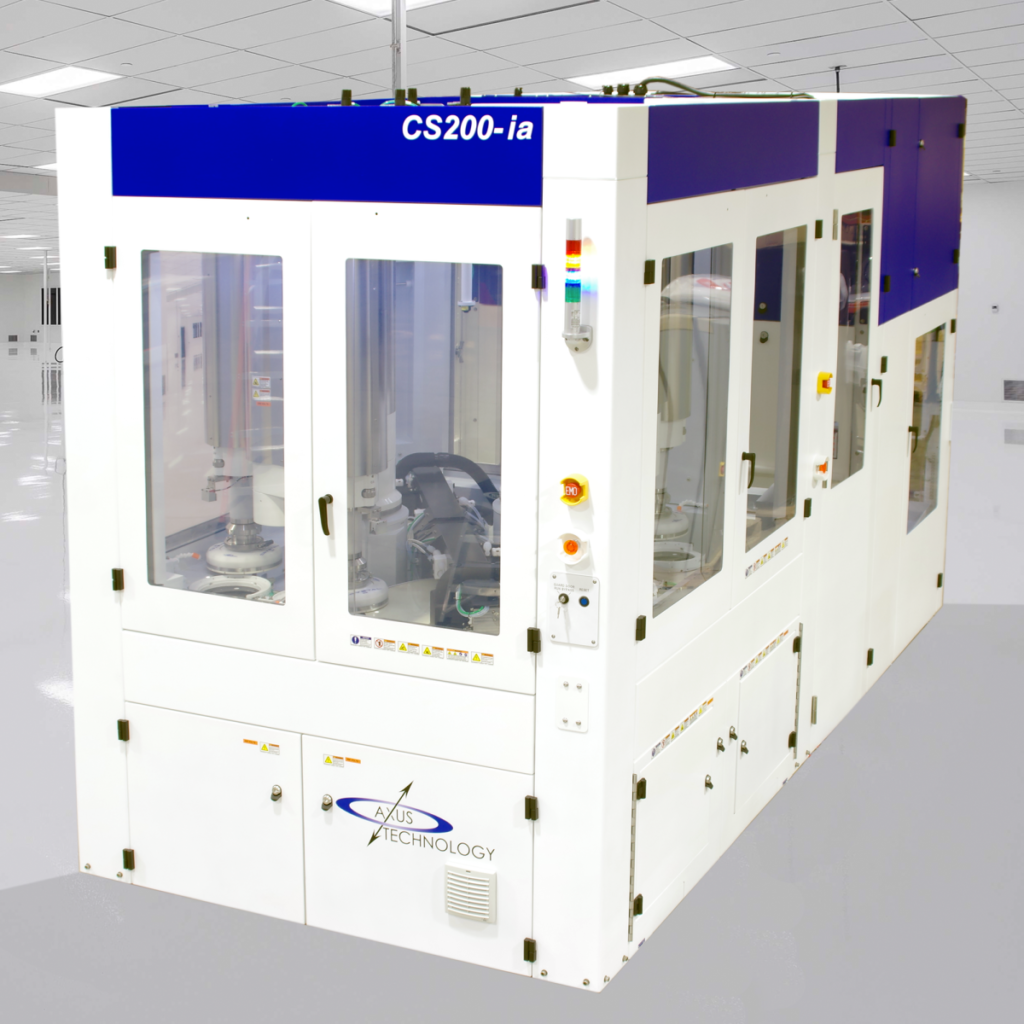

Axus Technology has received orders from the world’s leading SiC manufacturers for its Capstone CS200 platform CMP tools, including the Capstone CS200-ia model shown here.

CHANDLER, Ariz., July 08, 2024 (GLOBE NEWSWIRE) — Axus Technology, a leading global provider of chemical mechanical planarization (CMP) equipment critical to semiconductor and compound semiconductor manufacturing, today announced strong sales of the industry’s most advanced CMP processing tool, the revolutionary Capstone® CS200 Series. In recent months, the company has received orders from silicon carbide (SiC) semiconductor manufacturers based in Europe, Asia and North America.

The Capstone order includes R&D/engineering and production-ready tools, the latter configured for volume production of both 150mm and 200mm wafers, highlighting the platform’s flexibility and broad capabilities. Built using cutting-edge, flexible technology, Capstone is the first new 150/200mm CMP platform to market in over 30 years and the first platform capable of processing two different wafer sizes simultaneously, with tools that deliver the industry’s highest throughput and yields.

Continuous innovation drives progress

Axus Technology has continuously built out its offering since introducing its Capstone platform in 2020, introducing new SiC-optimized wafer carriers and achieving notable processing milestones along the way. The newest addition to the Capstone family, the Capstone CS200-ia, integrates the company’s Aquarius™ wafer cleaning system, enabling advanced CMP and post-CMP cleaning in a single system.

“Many of our customers are world-class SiC device and/or wafer manufacturers,” explains Katherine Block, director of process technology at Axus Technology. “These customers conducted extensive process and equipment testing to thoroughly evaluate and compare different solutions for advanced SiC CMP. We are proud that all of them selected Capstone as their preferred platform. This is especially important given the significant challenges and differentiation associated with CMP for SiC compared to more mature CMP applications.”

Capstone offers a unique differentiator

Capstone® offers several novel and differentiated competitive advantages driving growth in SiC CMP, including:

Flexible architecture capable of processing up to four wafers simultaneously, providing both the highest throughput and the smallest footprint for the lowest total cost of ownership (CoO).

Fully integrated advanced post-CMP cleaning allows both polishing and cleaning to be performed in a single pass, eliminating the need for additional post-processing wafer handling, downstream process steps and manufacturing equipment.

Ingenious process temperature control technology that allows for higher pressure/velocity process conditions – resulting in higher removal rates, higher throughput and reduced consumable costs – significantly improving overall CoO.

It significantly reduces energy and resource consumption, lowering operational and capital costs while improving environmental sustainability.

The story continues

“This is an exciting time for our industry,” said Dan Trojan, CEO of Axus Technology. “Silicon carbide is growing at a much faster pace than CMOS, driven by demand for AI data centers, renewable energy, and power electronics applications such as EVs. With our SiC engineering brain trust, proven product portfolio of CMP and related technologies, and a growing base of leading suppliers and SiC customers as evidenced by our recent surge in orders, Axus Technology is well positioned to become the industry leader in CMP for compound semiconductors.”

Axus consults with developers of SiC and other complex semiconductor devices to help them determine the best path forward for scaling production from 150mm to 200mm. The company has recently raised capital and is increasingly focused on expanding into HVM, allowing the company and its customers to work together to shape future strategies.

About Axus Technology

With its cutting edge Capstone® CMP and Aquarius™ wafer cleaning platforms, Axus Technology is a recognized industry leader in designing and building the latest, flexible next generation equipment and providing custom process development services. Axus empowers companies of all sizes, from start-ups to high volume manufacturers, to test, develop and implement cutting edge solutions, process integration schemes, products and applications, especially for new and emerging materials. Axus equipment solutions range from entry level tools with low cost of ownership to state of the art high volume production systems. Process testing, development, optimization and scaling are supported by our process application labs and foundries, which are fully equipped with process equipment and supporting metrology, and staffed by the most experienced CMP team in the industry. For more information, please visit www.axustech.com.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/4df53a23-247e-4e64-86fa-30aa783df5b4